Fixed Blade knife in Birdseye Maple

I finished my latest project, a fixed blade knife in birdseye maple. The knife blank is made by a Finnish company, Enzo, and this is their smallest knife, a model they call the Elver.

I bought the knife blank already formed and tempered, and I put on the handles, with red liners, and brass pins. I loaned a coworker an Elver to skin his elk, and it did great at a task that is real hard on knives. This knife is perfect for this purpose, or carving wood. Its a bit overkill for backpacking, but its fun to have a substantial knife in the backcountry.

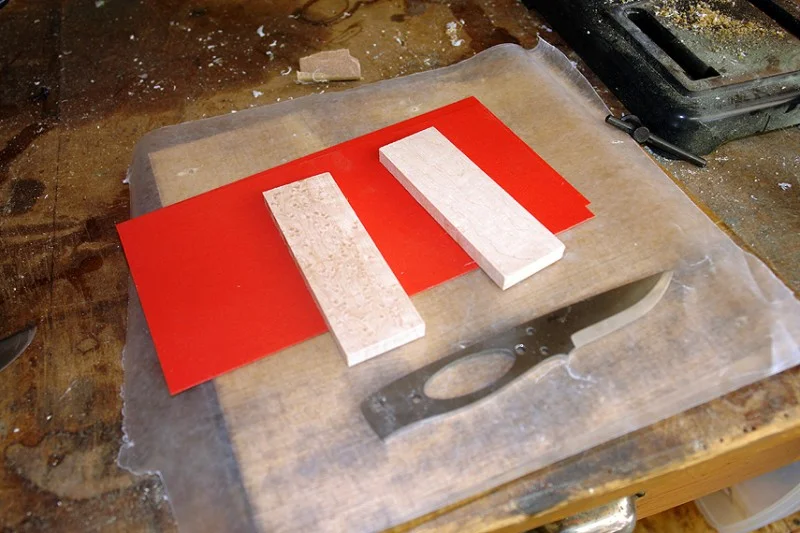

The blade blank, wood blocks (scales) and red liner material.

The scales drilled for bolts and lanyard tube, liners glued to the inside of the scales, everything epoxied together and clamped to dry.

This shows how much wood has to be removed, mostly with a hand rasp.

Detail of the side of the knife, showing the red liners. The handle was finished with three coats of tung oil for waterproofness, then three coats of shellac, the old time wood finish of violins and furniture.

The other side of the knife, showing the finger grooves on that side, and the flare at the back end, to enhance grip.

This view shows that this handle is not symmetrical. Factory made knives are generally ovalized in cross section, or flat with rounded edges. These shapes are easy to to, by use of belt sanders or a planer, and allow one shape to fit both left and right handers. With this knife I put finger groves on the left side, which fit nicely with my left handed grip. Those grooves are about where my first knuckle hit when loosely gripping with with the left hand. They also fit a right hand user's fingertips, so next time I'm going to put finger slots on both sides.

The coke bottle shape of the handle with a flare at the base all helps keep the knife from slipping out of the hand, a swell in the middle fills the hand for comfort, and the finger grooves add to the grip.